Single Vision Lens

Bifocal/Progressive Lens

Photochromic Lens

Blue Block Lens

Semi-Finished Lens

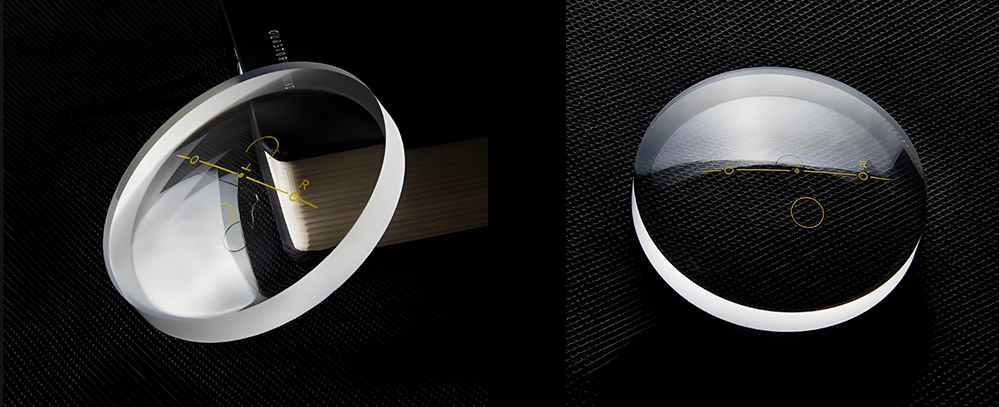

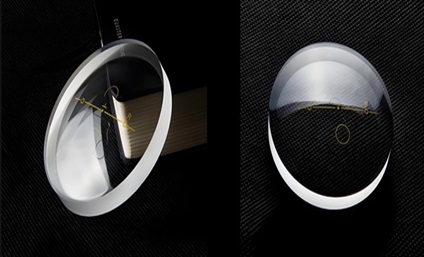

Myopia Control Lens

Lenses Glasses Moulds

Progressive Free Form Lens

Single Vision Lenses: Are They a Good Option for You?

Bifocal Lens vs Progressive Lens: How to Decide What’s Best

How to Choose Blue Block Lenses

Application Fields of Semi-Finished Lenses

How to Choose the Right Round Top Lens?

How Does the 1.56 Optical Lens Perform?

Myopia Control Lenses: A Powerful Tool for Vision Protection

Search

English

English