The optical industry relies heavily on materials and components that can be tailored to diverse requirements, and the semi finished lens stands as one of the most critical building blocks in lens production. Unlike finished lenses that are ready for direct consumer use, semi finished lenses offer manufacturers and laboratories the flexibility to process and customize lenses to specific prescriptions and functions. With decades of experience, Crystal Optical has become one of the leading semi finished lens suppliers, leveraging advanced technology and large-scale capacity to meet the growing demands of the global optical market.

The Core Role of Semi Finished Lenses in Lens Manufacturing

The semi finished lens acts as an essential intermediate stage in the lens production process. It comes in the form of a pre-moulded blank that has one surface already formed, while the other surface is left unfinished. This design allows laboratories to grind and polish the unfinished side according to individual prescriptions. For example, opticians can adapt the lens to meet single vision, bifocal, or progressive needs depending on the patient's requirements. This flexibility is why semi finished lenses form the backbone of prescription customization, making them indispensable in modern optical practices. Crystal Optical, with its 13,000-square-meter facility and daily output of 20,000 pairs of lenses, ensures a stable and high-quality supply for such needs.

Application in Prescription Eyewear

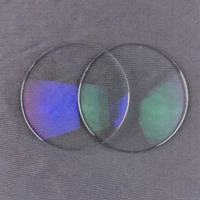

One of the most prominent application areas of the semi finished lens is prescription eyewear. Since no two patients share the exact same visual needs, the ability to fine-tune a lens for myopia, hyperopia, or astigmatism is crucial. Semi finished lenses allow laboratories to cut, grind, and coat lenses according to exact specifications. This not only ensures precision in correction but also makes it possible to integrate additional features such as anti-reflective coatings, UV protection, or photochromic functions. For suppliers like Crystal Optical, years of technological innovation and patent-backed processes allow them to produce semi finished lenses with consistent optical clarity and durability, giving opticians confidence in delivering reliable solutions.

Comparing Semi Finished Lenses and Finished Lenses

When evaluating options, it is important to understand the differences between finished and semi finished lenses, as each has unique applications.

Lens Type | Key Features | Application | Flexibility |

Finished Lens | Fully processed, ready for wear | Ready-made reading glasses, low-cost eyewear | Limited, cannot be customized |

Semi Finished Lens | One side pre-moulded, one side customizable | Prescription eyewear, advanced coatings, specialty lenses | High, adaptable to any prescription |

This comparison illustrates why semi finished lens suppliers play such an important role in the optical industry. While finished lenses are useful for mass-market, low-cost products, semi finished lenses provide the foundation for premium, customized eyewear solutions that meet the growing demand for individuality and precision.

The Importance of Reliable Semi Finished Lens Suppliers

In today's competitive optical market, selecting trustworthy semi finished lens suppliers is crucial for ensuring both consistency and quality. Suppliers must not only have advanced production capabilities but also demonstrate innovation, stability, and the ability to meet large-scale demands. Crystal Optical's collaboration with globally recognized companies such as Essilor highlights its strong position in the supply chain. By combining modern technology, extensive experience, and a commitment to quality assurance, the company exemplifies how a reliable supplier can drive value across multiple sectors of the optical industry.

In conclusion, the semi finished lens is more than just an intermediate product; it is the foundation of customized optical solutions. From everyday prescription glasses to specialized professional equipment, its wide range of applications demonstrates its importance in modern vision care and beyond.

Popular Search Terms from Crystal Optical

Insights into Prescription Eyeglass Lenses

English

English